Fishbowl Go

EASY-TO-USE & POWERFUL WAREHOUSE BARCODE SCANNING TECHNOLOGY

Take Your Warehouse To The Next Level With Powerful, Easy-to-use Barcode Scanning Technology

Barcode scanning is an essential element of any efficient warehouse operation. Fishbowl Go brings accuracy and efficiency to businesses by reducing manual double-entry and the need for excessive paperwork.

No more checking off items on pieces of paper then entering that information into a computer. With Fishbowl Go you achieve it all in the palm of your hand.

Fishbowl Go is a mobile app that integrates with Fishbowl Manufacturing® and Fishbowl Warehouse® to handle the physical inventory side of business. Access Fishbowl Go on any mobile device with Android or iOS operating systems, and use it to scan barcodes and perform many key inventory management jobs throughout your warehouse.

Get Fishbowl Go and accelerate your warehouse management processes

What is Fishbowl Go?

Explore the core features of Fishbowl Go

Inwards Goods

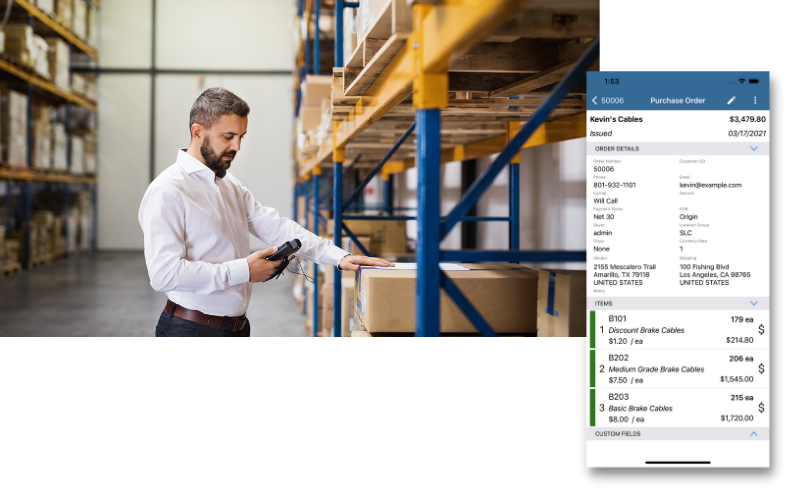

Scan to Create, Edit, and Receive Purchase Orders

The Purchase Order module in Fishbowl Go enables you to quickly receive incoming purchases from new and existing vendors via a smartphone, tablet, or other device. Use the Purchase Order module to avoid costly shortages and overstocks, while quickly receiving parts into your warehouse as needed.

One application is that you could create a Purchase Order by walking around your warehouse, and scan barcodes of items that are getting low and need topping up. Super fast and super easy!

Another application of this could be that you need to pop into a suppliers store to pick up some needed supplies, as you gather what you need you can scan the barcodes onto a new Purchase Order so that the items are all ready for you to Receive into Fishbowl for you to use.

In addition, you can add notes, taxes, and discounts to the items being sold. You can also create credit return and drop ship sales orders.

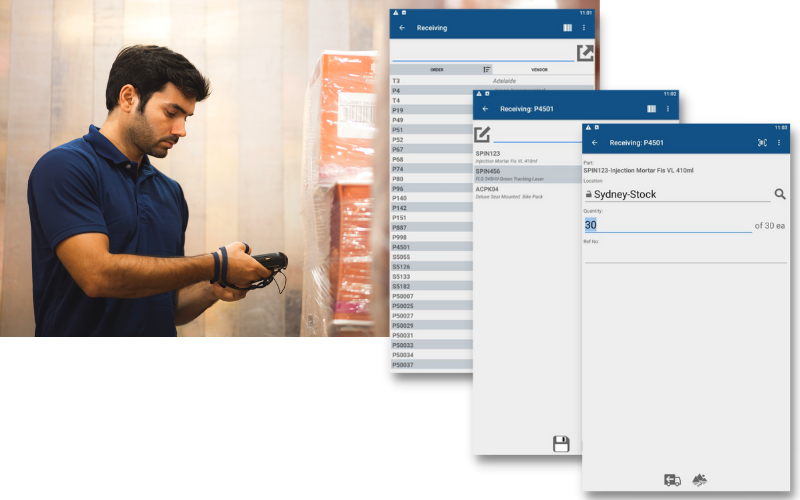

Scan Items in with the Receiving Module

With the simple scan of a barcode, you can receive inventory into your warehouse as it comes off the truck, make adjustments to quantities being received, and enter tracking information in real time. Receive parts with serial numbers, lot numbers, revision levels and expiration dates. Fishbowl Go even suggests where to place your incoming inventory, helping your workers become even more efficient.

Customer Orders + Dispatch

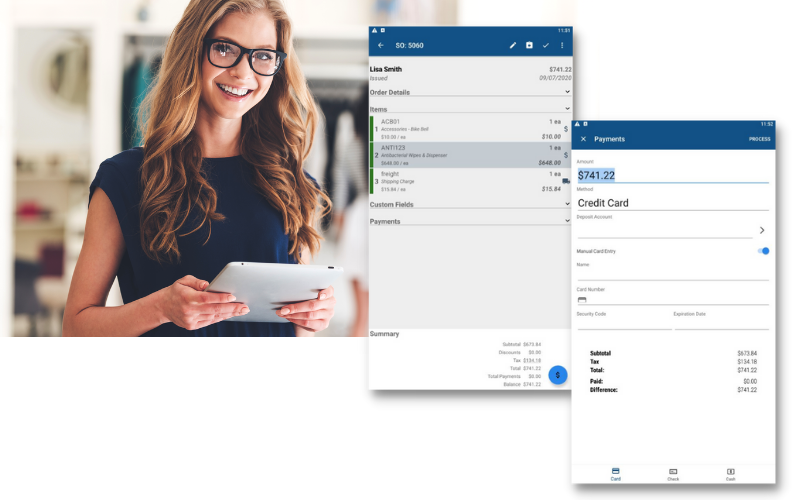

Create Sales Orders on the Go

The Sales Order module in Fishbowl Go lets you make and record sales on the go from new and existing customers using a mobile device. It gives you the ability to create, edit, issue, unissue, fulfill, and view sales orders.

You can even use it to create new parts to sell on the fly. Payments can also be taken within the app via cash, check, and credit card.

In addition, you can add notes, taxes, and discounts to the items being sold. You can also create credit return and drop ship sales orders.

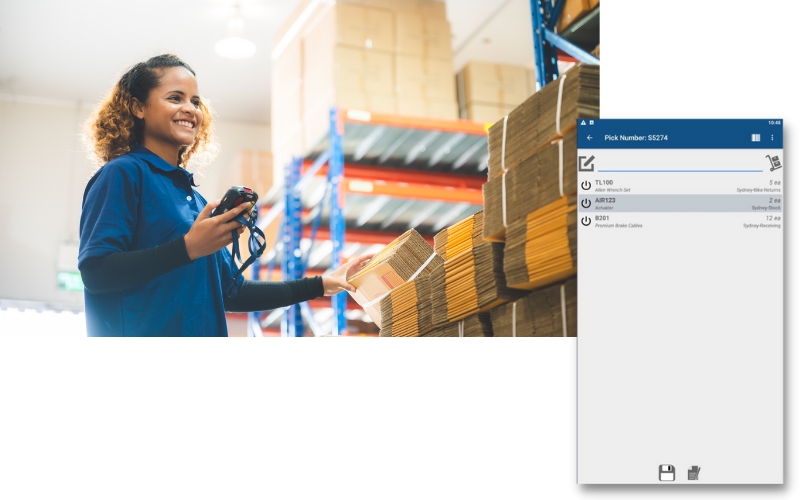

Pick quickly with accuracy

Fishbowl Go lets you start and finish a pick order right from your handheld device. Instead of having to print a pick order, the program walks you through your warehouse telling you where to pick and the quantity needed to fill your order. Save time by combining multiple orders and picking them simultaneously. Pick inventory for sales orders, work orders, transfer orders and vendor returns.

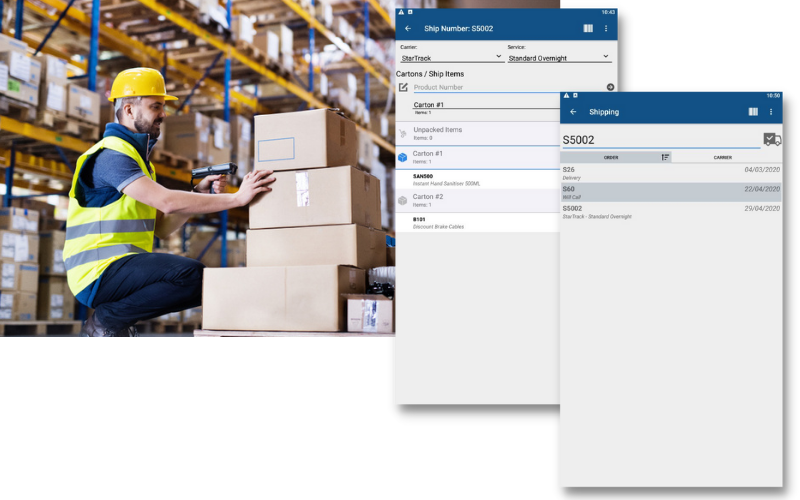

Pack and Ship on the go!

After all of the items in a sales order have been picked, they can be packed using the Pack module. You’ll be able to see all of the orders that have been entered and picked. Add the number of cartons you need to pack everything into and then assign each item to a carton.

If items have tracking information associated with them, you’ll see an edit screen pop up once you pack the items in a carton. This will help you modify serial numbers and quantities as necessary. And finally, you can select a carrier at the bottom of the screen to ship the order.

Once the order is shipped the order is fulfilled and will post to Xero, QuickBooks Online, or Reckon accounts as the Tax Invoice.

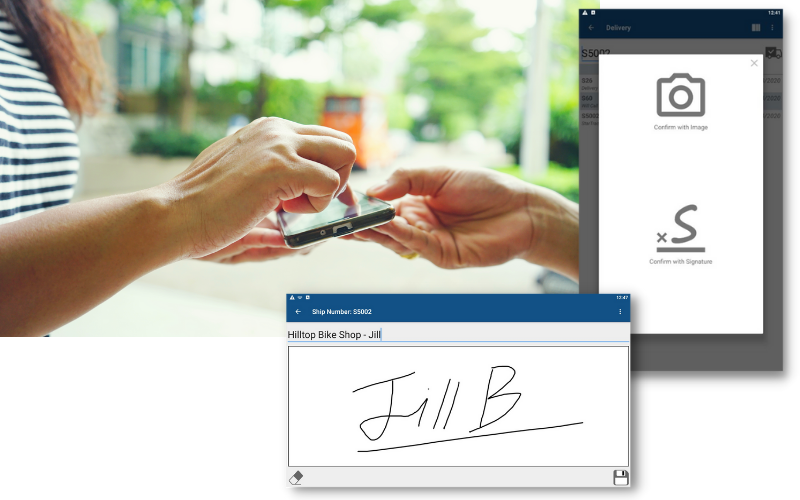

Proof of delivery capture

If you deliver to customers, or have customers come to collect their orders, the “Delivery” module in Fishbowl Go is fantastic.

When the diver arrives at the delivery location they open the order in the delivery module and select the “Confirm with Signature” option to obtain signature confirmation from the customer.

If you do not obtain a signature you can choose the “Confirm with image” option. This photo can show where the goods were left, or the condition of the items upon delivery.

These signatures and images are stored against the order in Fishbowl for you to refer back to if needed. This can be a big benefit to clear up any confusion and assure you that your customers are getting what they ordered on schedule.

Manufacture on the Go

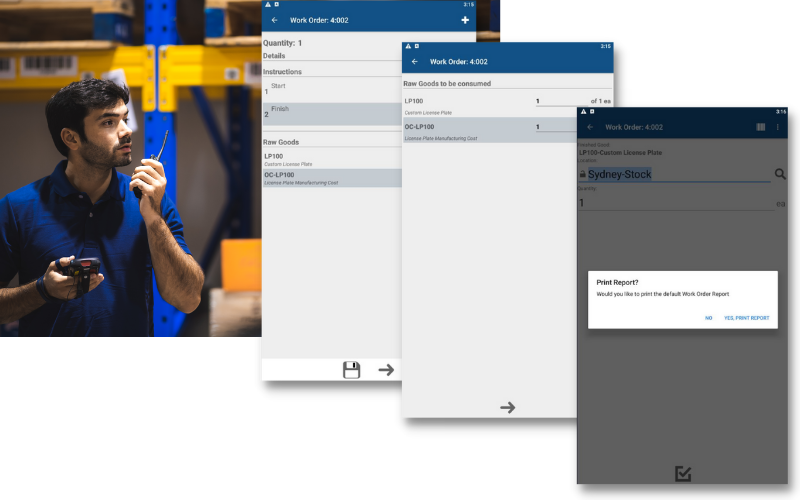

Complete Work Orders

You can finish work orders in Fishbowl Go’s Work Order module. Depending on the settings you have, you will be able to see only started work orders or both started and open work orders on this screen. When you click on a work order, it will display the raw goods contained in it. You can add more raw goods and pick them, if they haven’t already been picked.

The final screen shows you how many finished products will be manufactured from the raw goods in the work order, and you can update that number by clicking the “Add” button. Once you’ve completed a work order, add its tracking information and then click the “Finish” button.

Nice and easy.

Inventory Control

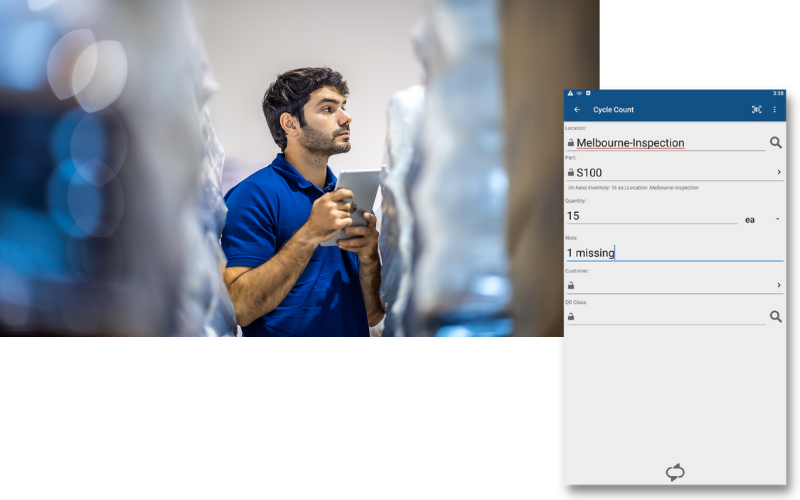

Stocktake done right. Fast and Accurate!

Fishbowl Go makes updating product quantities much easier with its cycle counting feature! It is basically a combination of the Add Inventory and Scrap modules.

You can adjust inventory up or down depending on the discrepancy you notice between the quantity that is in your inventory records and the quantity that is actually on the shelf. Check out our Cycle Counting Inventory Page to learn more.

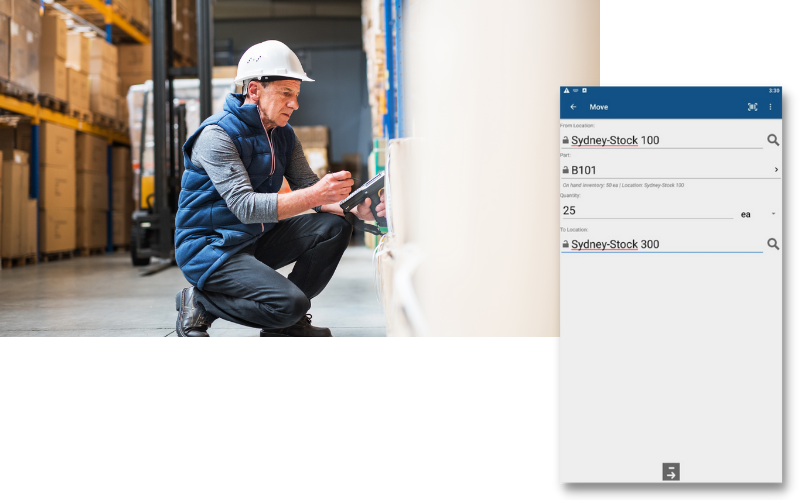

Move Inventory on the move

Keep your warehouse up to date by recording inventory movements as they happen. Many inventory discrepancies occur as the result of misplaced, moved or poorly recorded parts.

Rather than trying to keep track of which parts are moved to new locations and entering changes after the fact, Fishbowl Go allows you to simply scan the Location and Part bar codes to record the move of your inventory. You’ll save time by recording the movement of inventory as it occurs.

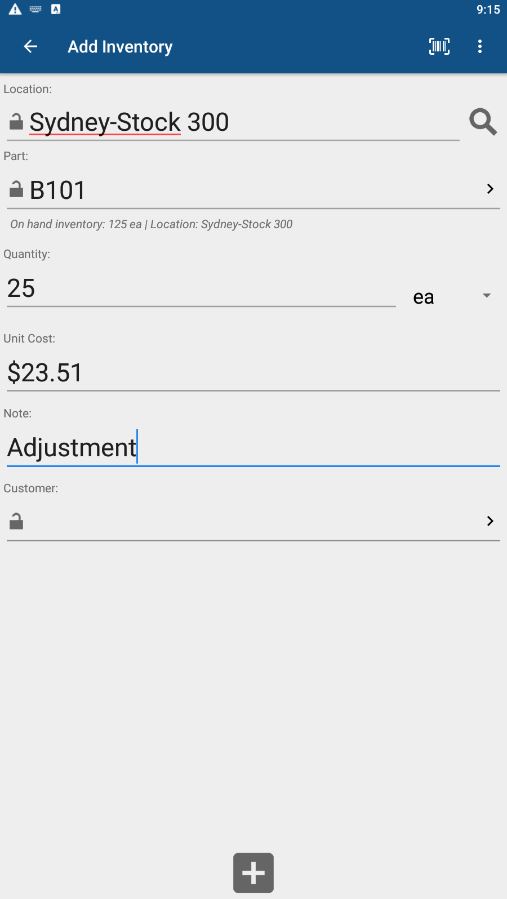

ADD INVENTORY WITH THE SCAN OF A BARCODE

This module is pretty self-explanatory. You can use Fishbowl GO to add to the inventory quantities you have in stock. Simply go to the Reports module and print barcodes for all of your parts and locations. When you want to add inventory, scan a location first, then scan the part you want to add inventory to at that location, and type in the quantity you are adding. You can also manually enter locations, parts, and quantities. If you’d like to add tracking information to items, enter or scan the new tracking criterion and click the “Add Inventory” button.

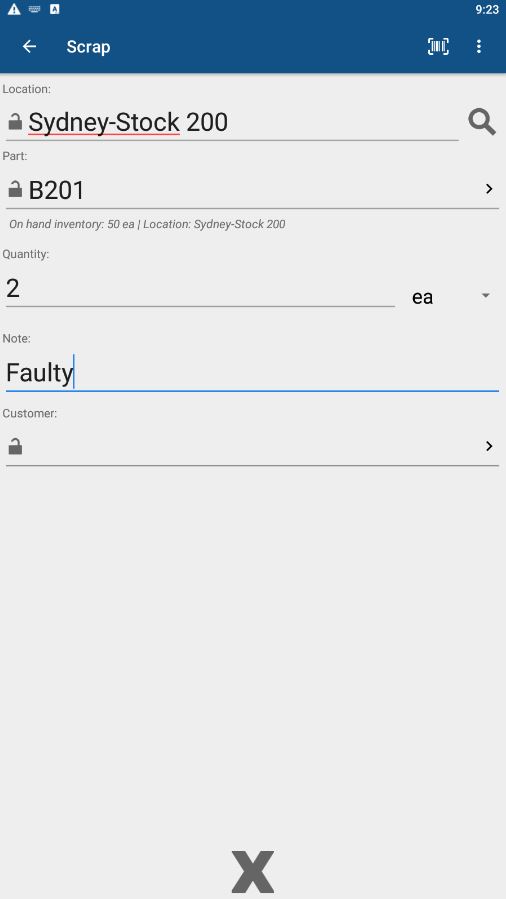

SCRAP INVENTORY BY LOCATION

Sometimes an item gets damaged or worn out, so it becomes necessary to throw it out. That’s what the Scrap module is for. It’s the reverse of the Add Inventory module. Like that module, this one relies on part and location barcodes to let you scan the ones you’re working with, but you can also do it manually. When you want to scrap items in your inventory, scan their location and then the items themselves. After that, simply enter the quantity being scrapped and their tracking information, if necessary.

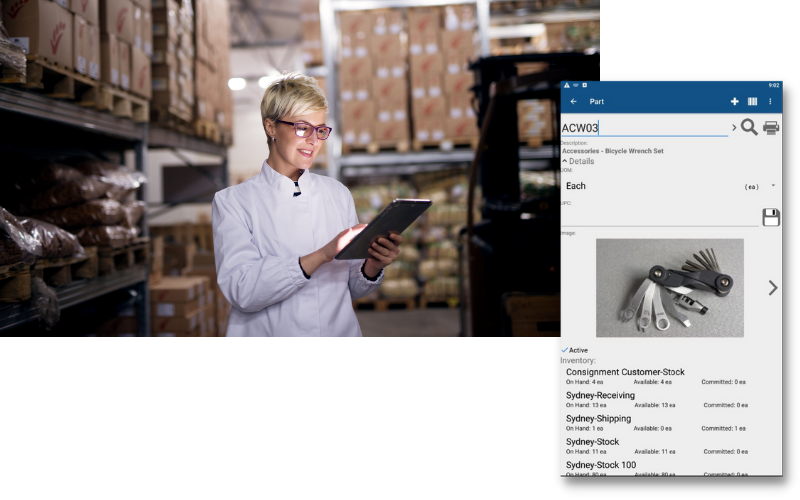

Retreive part information

Quickly and easily look up part descriptions, UPC’s, and real-time part tracking information. Use existing UPC’s, serial & lot numbers, expiration dates, or Fishbowl-generated barcodes to manage your inventory with accuracy and efficiency. You can even assign new or updated UPC’s.

If you’re using a wireless device and happen to leave your coverage area, your data is automatically preserved and ready to resubmit once the connection is reestablished. Also, Fishbowl’s security settings let you customise access rights by user.

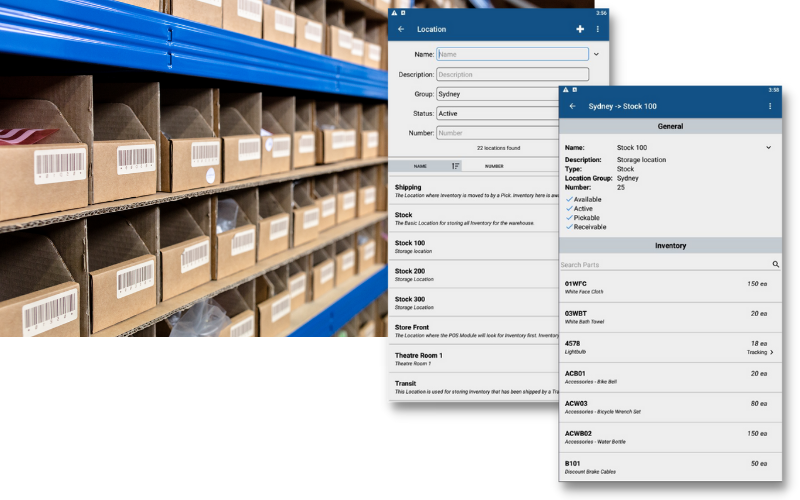

Access, View, and Create Locations

The Location module in Fishbowl Go lets you search for any location in Fishbowl by its name, description, location group, status, and/or tag numbers. This gives you the ability to quickly check inventory counts and tracking information for parts within any location.

You can even create brand-new locations in the Fishbowl Go Location module. This is an essential tool for any business wanting easy access to warehouse locations and inventory counts on the go.

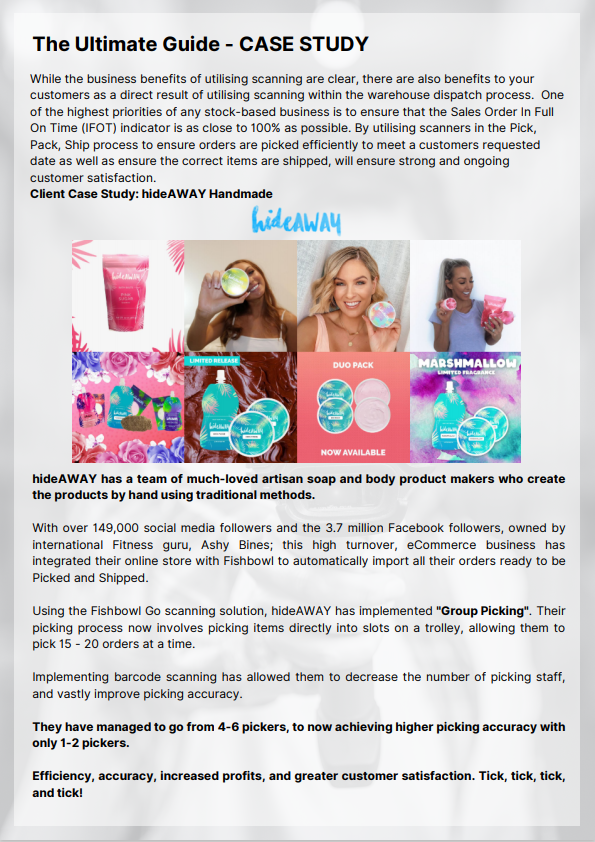

Barcode Scanning Case Study

Watch the Fishbowl Go Commercial

Take your warehouse to the next level by incorporating powerful, easy-to-use barcoding technology. Fishbowl Go lets you view and adjust inventory levels from anywhere in your warehouse and makes quick, accurate Stocktakes, a normal way of life.

Whether you are shipping, receiving or simply moving inventory from one location to another, Fishbowl Go will help you increase your inventory accuracy and worker productivity with ease!

See all of the ways you can use Fishbowl Go in your business.

Fishbowl Go FAQs

How Many Items Can Be Tracked On Fishbowl Go?

With Fishbowl Go, you can track an unlimited number of items. This makes it easy for you to keep track of your inventory and sales orders. You can also use the barcode scanner software to scan products in your store or warehouse. Product scanning is a quick, efficient way to track items, and helps you keep track of products that are selling and those that are not.

Can Fishbowl Go Barcode Scanning Also Print Labels?

One of the main benefits of barcode scanning technology is that it eliminates the need to enter product information manually. This can be a time-consuming process, but with barcode scanning technology, all you have to do is scan the barcode and the product information will be presented automatically. Barcode scanning technology can also be used to print labels. If you have multiple products that need labelling, you can use a barcode scanner to create a label template. This will save time and money, as you won’t need to hire someone to create custom labels for your products.

Can Fishbowl Go Scan Multiple Barcodes At The Same Time?

Yes, multiple barcodes can be scanned at the same time with barcode reader software. The barcode reader software included with Fishbowl Go makes scanning barcodes quick and easy. This is helpful for businesses that need to scan a large number of items in a short amount of time. Thanks to our Barcode Reader Software, Fishbowl Go can save businesses valuable time and money.

How Do You Link Fishbowl Go With Other Devices?

Fishbowl Go eliminates the need to manually enter product information. In addition to tracking barcode scanning, Fishbowl Go can also track stock levels and quickly find products in your inventory. Barcode scanning technology can be used with other devices, such as desktop computers and laptops, allowing you to scan barcodes and then import the information into Fishbowl. This is a quick and easy way of adding products to your inventory database.

What Barcode Formats Does Fishbowl Go Support?

Barcode scanning technology is used to read barcodes and QR codes. Barcodes are linear, two-dimensional symbols that represent data, such as prices or product SKUs. QR codes are square matrices that can store more information than barcodes. There are a variety of barcode formats, and Fishbowl Go supports all major formats. A barcode scanner software application is necessary to scan barcodes and QR codes with a device’s camera. Barcode scanner software applications are available for devices running the Android, iOS, and Windows operating systems. Some scanners are equipped with their proprietary scanning software, while others rely on scanning software that is bundled with the device’s operating system.

Contact Us

Give us a call and have a chat with one of our amazing client solutions team

AU: 1300 785 755

NZ: 0800 785 755

solutions@fishbowlinventory.com.au

No credit card details required. Enter your details and download your free trial now!

Instructions

Just fill in the information and click the GET STARTED button to access our download. The free-trial versions are fully functional copies of our software with all capabilities enabled. A Fishbowl technician will contact you — usually within two business days — to help answer any questions you may have.

Important: We will never sell your information to third parties.